Magnetics at Extreme Conditions: Exxelia to Showcase Innovations at APEC 2024

Exxelia is thrilled to announce its participation in the upcoming APEC 2024 conference to be held in Long Beach, California, USA.

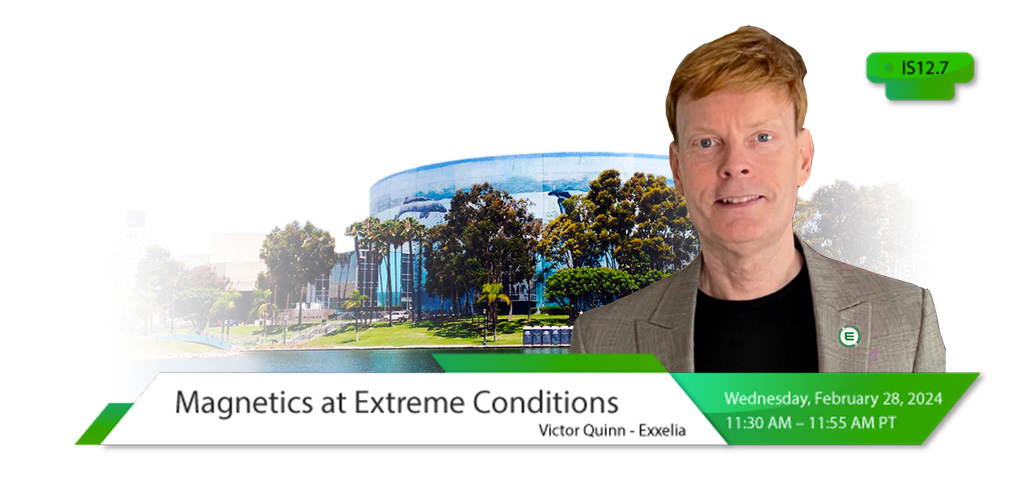

The event will feature a compelling presentation by Exxelia's own Victor Quinn* on the topic of "Magnetics at Extreme Conditions" as part of the EMI & Magnetics session.

The event will feature a compelling presentation by Exxelia's own Victor Quinn* on the topic of "Magnetics at Extreme Conditions" as part of the EMI & Magnetics session.

Victor Quinn, a expert in the field, will delve into the intricacies of magnetic components and their performance under extreme conditions. With a focus on Exxelia's cutting-edge innovations, the presentation promises valuable insights into the challenges and solutions in the realm of electromagnetic interference and magnetics.

Victor Quinn, a expert in the field, will delve into the intricacies of magnetic components and their performance under extreme conditions. With a focus on Exxelia's cutting-edge innovations, the presentation promises valuable insights into the challenges and solutions in the realm of electromagnetic interference and magnetics.

About the Session:

The EMI & Magnetics session at APEC 2024 is a platform for industry leaders and experts to share their knowledge and advancements in electronic components. Victor Quinn's presentation will shed light on Exxelia's commitment to pushing the boundaries of what is possible in the world of magnetics, especially in environments with extreme conditions.

The target audience is electronics and magnetics design professionals, component engineers, purchasing agents and design engineers who develop components used in magnetics for extreme conditions.

Why Attend:

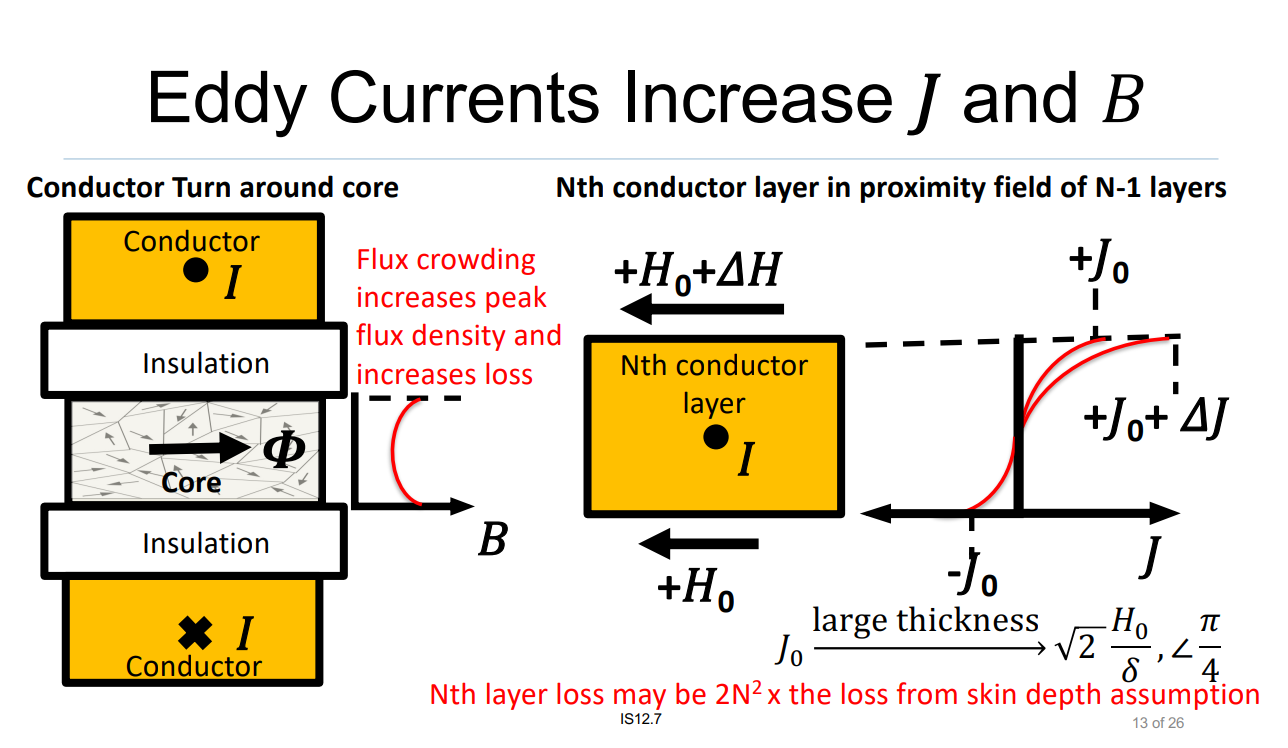

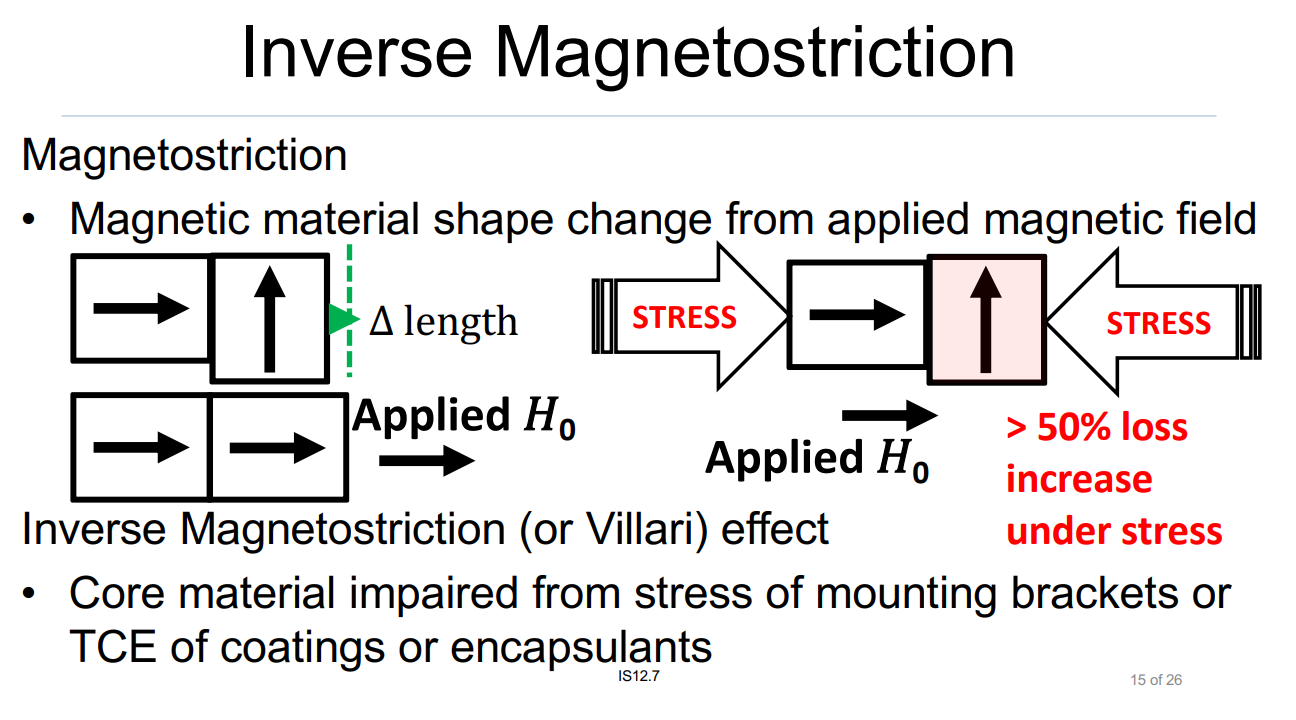

This presentation considers engineering methods to develop magnetic components for selected extreme power electronics conditions. These extreme application conditions include environmental and electrical operating conditions that compel unusual design and development processes, component materials, test methods and other controls to assure high reliability. Presentation content will help designers and project managers understand methods of risk management when magnetics are required for highly demanding applications.

Primary goal is to help power electronics professionals prevent excessive design iteration and reduce risk of unexpected magnetics failure for systems operating in extreme conditions. Recommended design experiments, empirical test methods and qualification methods will be provided.

The second goal is to help other professionals involved in the development of components for magnetics further anticipate component requirements for magnetics in extreme conditions.

- Innovative Solutions: Learn about Exxelia's latest breakthroughs in magnetic component technology.

- Expert Insights: Benefit from Victor Quinn's extensive expertise and experience in the field.

- Networking Opportunities: Connect with industry professionals and explore potential collaborations.

Exxelia invites all attendees to join this insightful session to explore the fascinating world of magnetics and its applications in extreme conditions.

Be sure to mark your calendars for Wednesday, February 28, 2024, at 11:30 AM PT, and don't miss the chance to be part of this engaging presentation.

Event Details:

Presentation Number: IS12.7

Title: Magnetics at Extreme Conditions

Session: EMI & Magnetics

Date: Wednesday, February 28, 2024

Time: 11:30 AM – 11:55 AM PT

We also invite you to chat with our teams at our booth 938

* About Victor W. QUINN

- Title: Director of Engineering and Technology

- Affiliation: Exxelia USA

- Biography of Presenter:

Victor W. Quinn manages Exxelia’s US Magnetics Design Center with responsibilities for research and technology implementation on new products. With degrees in Physics and Electrical Engineering, since 1980 Mr. Quinn has specialized in magnetic component design and development for a wide variety of industrial, aerospace, space and defense applications. His original APEC publication was in 1994 concerning planar transformers and later a professional advancement course in expert transformer design was given at APEC 2006. He holds a longstanding interest in advancing magnetic components using improved design and empirical test methods and developing novel technologies that increase volumetric efficiency. Mr. Quinn has been granted multiple patents and others pending related to these efforts.

Victor W. Quinn manages Exxelia’s US Magnetics Design Center with responsibilities for research and technology implementation on new products. With degrees in Physics and Electrical Engineering, since 1980 Mr. Quinn has specialized in magnetic component design and development for a wide variety of industrial, aerospace, space and defense applications. His original APEC publication was in 1994 concerning planar transformers and later a professional advancement course in expert transformer design was given at APEC 2006. He holds a longstanding interest in advancing magnetic components using improved design and empirical test methods and developing novel technologies that increase volumetric efficiency. Mr. Quinn has been granted multiple patents and others pending related to these efforts.